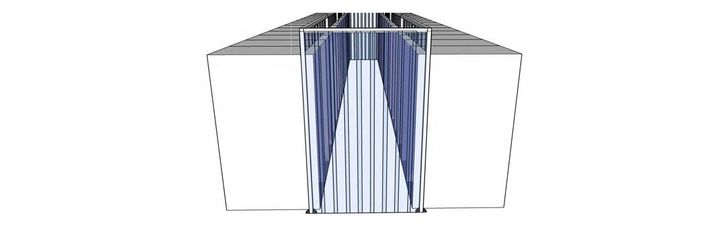

Inexpensive soft cold aisle containment with fire-retardant curtains

The Daxten CoolControl Curtain Aisle Containment sytsem is a cost-effective solution for improving the cooling efficiency in data centres. The system is made of an inert and non-conductive synthetic material that is self-extinguishing according to the EN DIN 53382 standard. It is compatible with all conventional rack dimensions and can be easily integrated into environments that have evolved over time with racks from different manufacturers. Cold aisle containment with the CoolControl Curtain solution can reduce cooling output and energy consumption by up to 30 percent in data centres. This solution can also be used to as a planning tool to calculate the potential savings before an investment is made in complete physical containment.

Recirculation of warm air in racks can cause high energy consumption of cooling systems

Cold aisle containment stems from the fact that active hardware in a rack takes in cold air at the front of the rack and directs it to the back once the air has cooled. This warm air rises up at the back of the rack and flows back to the front of the rack where it is cool. The hot air can also recirculate through openings between rack units in the rack or along both sides of the cabinet to the cold aisle. As this process repeats, the temperature in the cold aisle gradually rises. The most common way to counteract this phenomenon used to be to increase the output of the cooling systems which in term led to huge energy bills for the entire data centre.

The CoolControl Curtain Aisle Containment lowers the electricity consumption of cooling systems by up to 30 percent

It is thus nowadays essential to hermetically seal the hot air from the cold aisle between the rack fronts. The CoolControl Curtain is a reliable way to guarantee aisle containment. Our measurements have shown that by installing CoolControl Curtain, the temperature difference between the hot and cold aisle can be as high as 10-15 degrees Celsius. Depending on the size and environmental specifics of individual data centres, the cooling output of the systems have been able to be decreased by as much as 30% which has also lowered energy consumption accordingly.

Getting the most out of cold aisle containment

Below are best practice recommendations for how to maximise the benefits of the containment solution both functionally and in terms of the potential energy savings.

Rack front panels

We can, without reservation, recommend using simple plastic panels to seal off unoccupied rack units at the fronts of the contained racks in the cold aisle. This measure, which costs less than £2.00 per rack unit, eliminates an often overlooked weak point in cold aisle containment: it prevents the hot air exhausted to the warm aisle by the active hardware from recirculating back through the rack to the cold aisle and increasing the temperature in the isolated aisle which then has to be compensated for by increasing cooling system output.

Airflow panels in the cold aisle ensure optimum cold air supply and constant pressure for containment

Another important component to achieve maximum efficiency of cold aisle containment are hi-plume airflow panels which provide a steady supply of cold air from the raised floor with constant pressure. It is extremely important to find the right balance of cold air pressure in the contained cold aisle – not only to avoid energy inefficiency when cooling but, if the pressure is too high, to prevent the server fans which are in standby mode from starting as this could damage the hardware.

Prevent bypass airflow and thermal imbalances in the rack by sealing cable openings in the raised floor

The best containment is of no use energy-wise if the cold air generated by the cooling systems escapes to the cold aisle through unsealed cable openings in the raised floor before it reaches the airflow panels. These holes can be plugged with baffles made of non-flammable melamine resin foam or with grommets. Not to be forgotten is the bypass airflow in the rack itself which can lead to thermal imbalances and, in the worst case, to the formation of hot spots through cable openings in the floor. This problem can be remedied with special raised floor baffles with integrated grommets or using accordion-shaped plastic baffles with adjustable holes through which the supply cable can be guided from the raised floor to the rack with no loss of air.

Reduce airflow corridors in the raised floor and direct the cooled air to the airflow panels in the cold aisle

Last but not least, you should take also take a look in the raised floor. It can make sense to reduce the airflow corridors of the cold air and route it directly to the baffles in the cold aisle so that it doesn’t escape, spreading across the entire interior volume of the raised floor and thus reducing the airflow rate and pressure. Airflow diffusers made of non-flammable plastic can be easily installed along the raised floor pedestal. They direct the flow of air, ensure that the cooled air is used more efficiently and reduce the output of the cooling systems.

Cold aisle containment highlights

- Inexpensive separation of warm and cold aisle

- Prevents warm air from recirculating to the cold aisle

- Achieves a temperature difference of 10 to 15 degrees Celsius between cold and warm aisle

- Up to 30% energy savings for cooling

- Reduces output of the cooling systems

- Requires just a few hours to install

- Ideal tool for planned structural containment Inexpensive separation of warm and cold aisle

- Compatible with the rack dimensions of all manufacturers

Download

Download our white paper on how to make the right choice of the best aisle containment system for your data centre: White Paper Aisle Containment